The Galvanic Series and Corrosion Coupons

Sources of galvanic corrosion can show up in subtle or unexpected ways. For example, a common mistake is to install a copper corrosion coupon up stream of a carbon steel coupon in a corrosion coupon rack. When the copper corrosion coupon corrodes, copper ions dissolve into the water and can plate on the steel coupon, galvanic attack will then accelerate corrosion of the steel coupon. This can lead to significantly higher steel corrosion rates.

In systems where corrosion coupons of various metals are in use, such as in a coupon rack, special care should be taken to ensure the coupons are installed in order of nobility.

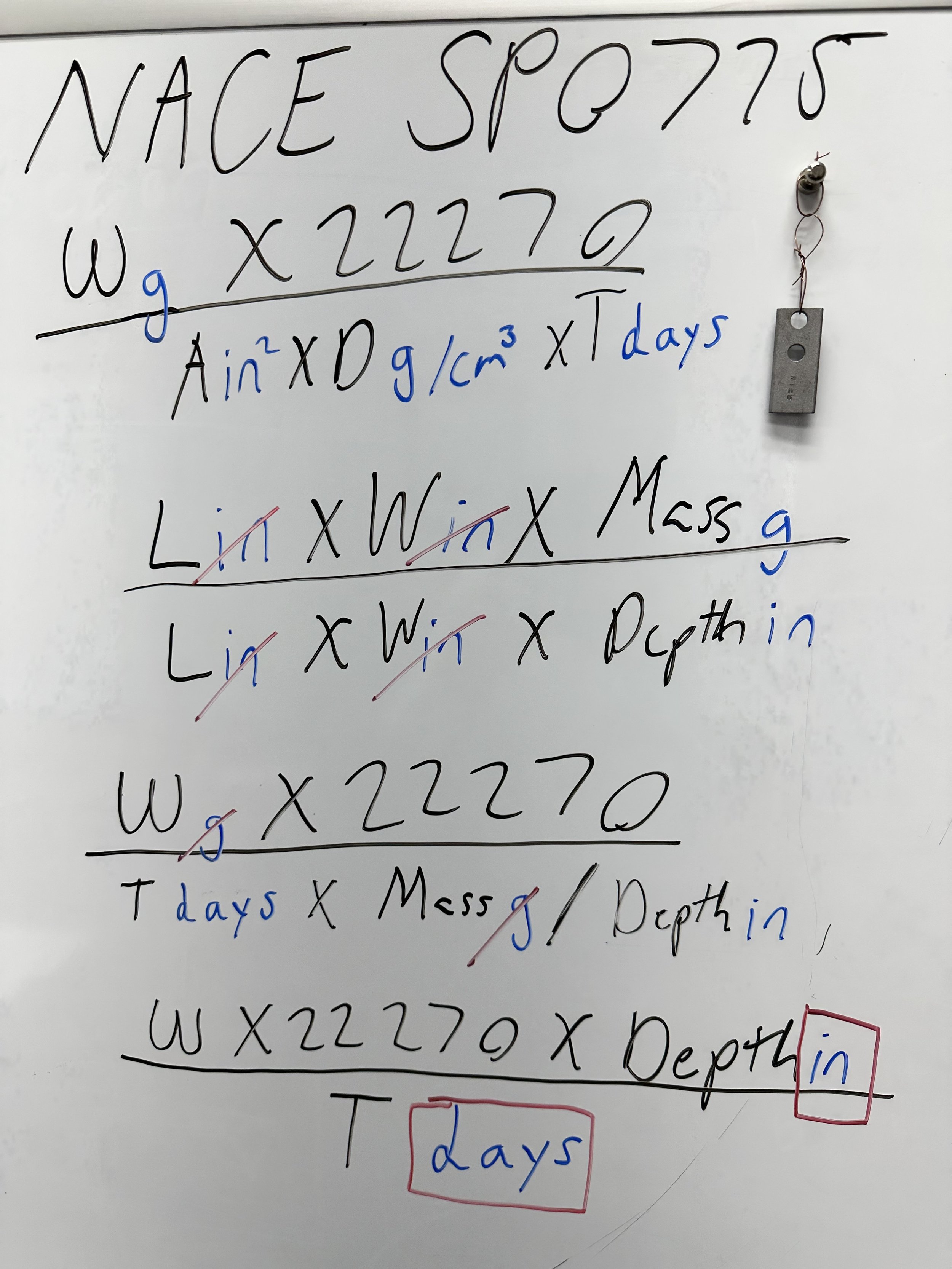

The Math Behind Corrosion Rates NACE SP0775

Corrosion coupons are in common use in the oilfield and many of us use the formula from NACE SP0775 daily to calculate corrosion rates by mass loss, but have you ever stopped to think how this formula was derived? How is it that we report “mils per year” (mpy) but there are no “mils” anywhere in the formula nor are there any years? If you are as dense as I am (pun intended) you may be inclined to think of this like you do “miles per hour” which is very clear to me that the miles are in the numerator and hours in the denominator (m/h). Likewise, I would expect to see mils in the numerator and years in the denominator in the formula for mils per year (m/y) but alas no mils and no years can be found. What gives? Let’s break this down and see if we cannot figure out what is going on here.

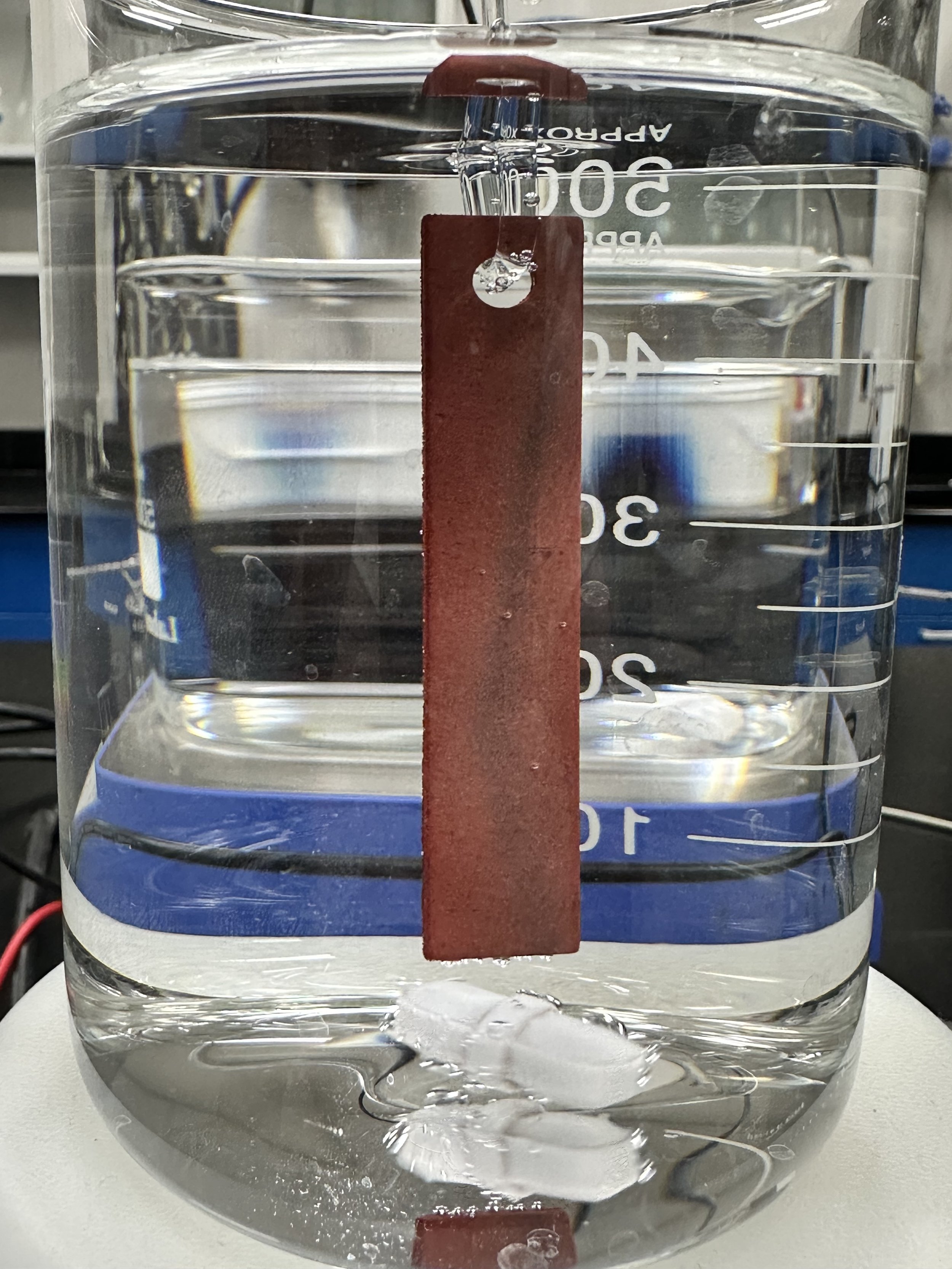

Corrosion Coupons - An Introduction

Corrosion coupons are the simplest and most cost-effective way to monitor internal corrosion in pipelines, plants and process equipment. The purpose of corrosion coupons is to give the operator of the equipment an estimate of the rate at which the pipe or equipment is corroding from the inside out. In other words, how corrosive is the fluid or vapor inside the system? Knowing the rate of corrosion will allow the operator to gage the effectiveness of the corrosion mitigation program and determine if any changes are needed. A proper corrosion monitoring and mitigation program is critical to preventing corrosion related failures. Failures in production equipment can result in death or serious injury, environmental disasters, litigation and destruction of property, plant, and equipment. The largest consumers of corrosion coupons are the oil & gas, water treatment, chemical, and laboratory industries.